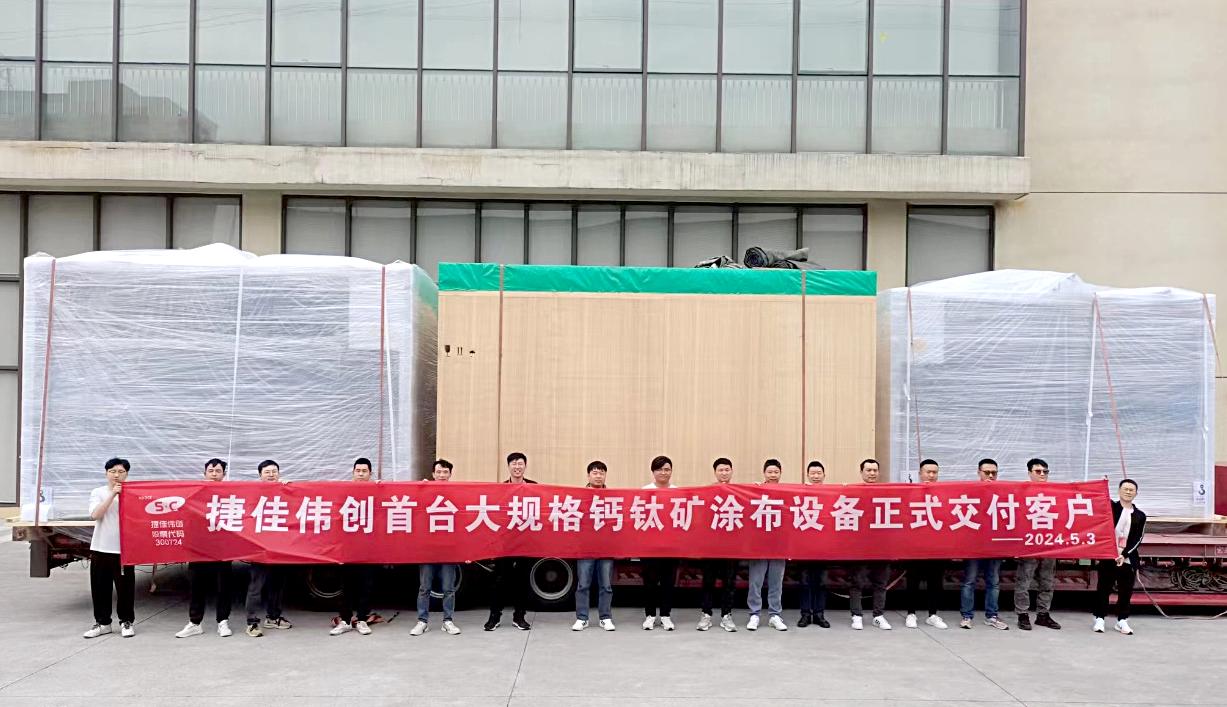

Large-Size Perovskite Coating Equipment Successfully Delivered

Recently, S.C's self-developed key equipment for perovskite solar cell production, Large-Size Perovskite Coating Equipment, is officially delivered to the customer. The equipment will be incorporated into the customer's pilot line for full-scale production, and help the customer improve the industrialization of perovskite solar cell process route. As more sets of PSC process equipment are gifted with mature R&D, S.C's R&D and competitive strength in the field of PSC will continue to improve.

The Large-Size Perovskite Coating Equipment is a much-needed type of critical core equipment for the industrialization of perovskite solar cell. S.C owns full independent intellectual property rights to its perovskite coating equipment, which is applicable to the preparation process of PVK layers/PSC functional layers/PSC passivation layers. The equipment has innovatively applied the temperature and humidity control system and the high precision detection and protection system. It can also be automatically connected in series to the complete production line. The liquid piping system of the equipment has the functions of automatic chemical change and inline cleaning, while the software used is an independently developed program that controls the ACS high precision motion controller. Through S.C's continuous innovation in technology, the equipment has met the customer's technical requirements.

In recent years, S.C has continued to gain insight into the development trend of photovoltaic technology, increase investment in research and development, and take the initiative to develop new processes and technologies. We have continuously achieved major breakthroughs in the research and development of core equipment for perovskite solar cell production. We have the ability to provide all sets of equipment for the complete production line of perovskite solar cells, and we are able to meet the equipment needs of the continuous growth of perovskite solar cell industry, and create more values for our customers.