Innova-TRON Leads the WAY Into the Future - Tronway at SEMICON China

From June 29th to July 1st, 2023, the China International Semiconductor Equipment, Material, Manufacturing and Service Exhibition (SEMICON China) was held in Shanghai. As the world's largest and most influential professional semiconductor exhibition, the exhibition covers the entire industry chain, including chip design, manufacturing, assembly and testing, equipment, materials, photovoltaic, display, etc. Leading companies and professionals from the semiconductor industry at home and abroad gathered in Shanghai to share technical insights and discuss the development of the industry.

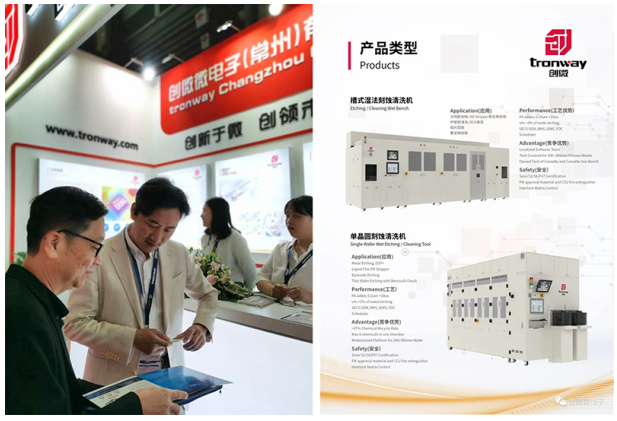

Tronway Changzhou Co., Ltd. ("Tronway" for short), a subsidiary of S.C, has been a specialized manufacturer of high-end semiconductor wet cleaning equipment ever since its establishment in September 2020, and has gradually gained the support and recognition of the industry and users thanks to our internationalized team and localized manufacturing. Tronway, along with its self-developed advanced technological achievements, took part in SEMICON China, attracting a large number of industry partners to Tronway's booth for visits, discussion and cooperation, and also obtaining several pending orders.

Our Tenacity for Localization & Our Notable Achievements

Our company was, and still is, committed to the localization strategy. Currently, we are leading the domestic progress in localizing the batch-type wet bench tool, with an overall localization rate of up to 90%. We have achieved domestic processing and cooperative development of our home-developed components such as DI water heaters, dryers, PTFE & PFA components, quartz components, heat exchangers, pipe fittings, etc., successfully breaking the Japanese and Korean monopoly. Concurrently, our company is leading our upstream and downstream component partners on a path of shared growth, helping them to obtain relevant certifications, successfully replacing American and Japanese equipments, and gaining recognition from leading customers in the semiconductor industry.

As for the software, our software engineers represent 30% of our staff. We have a self-programmed and self-designed software system, with all programming codes independently owned and completely free from the restrictions of foreign manufacturers, so that the process programs for manufacturing can be customized for the customer in a timely and efficient manner.

On a Promising And Futuristic Path Towards 12-Inch Cleaning Tool

The company continues to expand R&D investment and move towards high-end cleaning tool. We are developing the large-scale 12-inch cleaning tools required for the sub-28nm process, mainly including Wet Bench Tool and Single Wafer Wet Process Tool, which will be another milestone in our company's equipment R&D and localization progress.